Nov 26, 2025

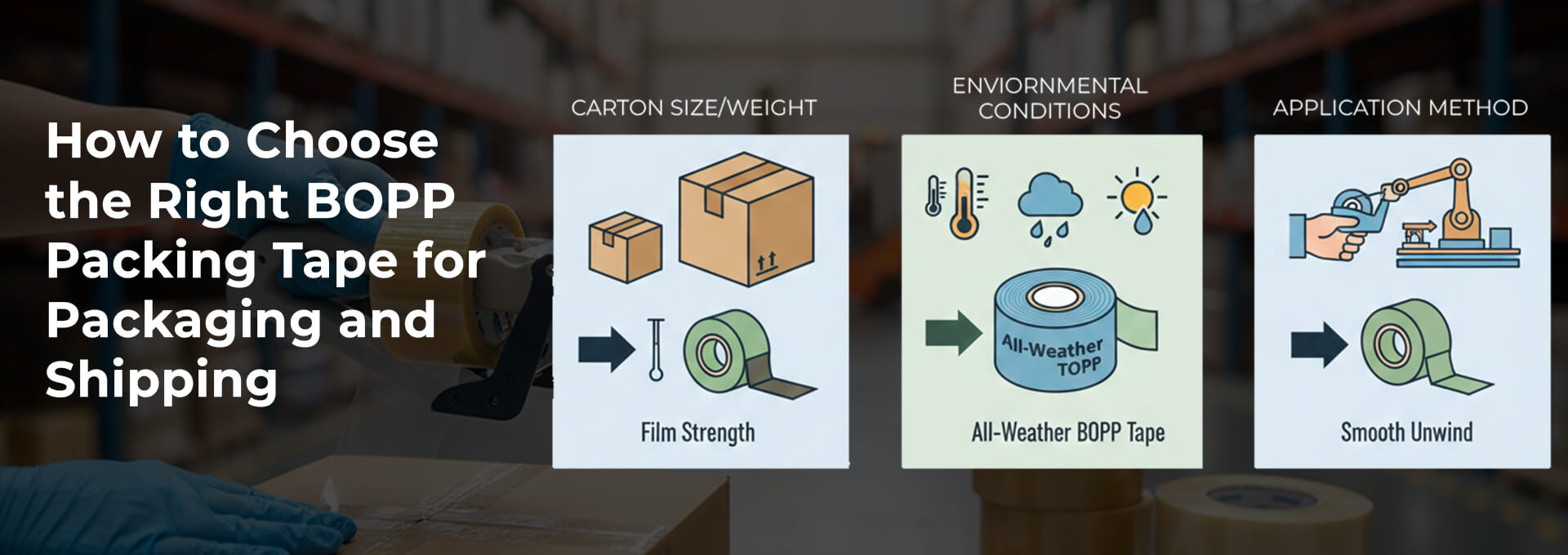

How to Choose the Right BOPP Packing Tape for Packaging and Shipping

Selecting the right packing tape is essential for ensuring product safety during storage and transportation. Incorrect tape selection can lead to carton failure, damaged goods, increased returns, and higher operational costs. Businesses involved in packaging and shipping must consider several practical factors to achieve secure and reliable sealing.

This guide explains how to choose the most suitable BOPP packing tape based on packaging requirements, handling conditions, and shipping needs.

Understand Your Packaging Requirements

The first step in selecting the right tape is evaluating the nature of the packaged goods. Factors such as carton size, weight, and material directly influence tape performance.

Heavier cartons require stronger packing tape with higher tensile strength, while lighter packages may perform well with standard specifications.

Consider Adhesive Strength

Adhesive strength determines how well the tape bonds with carton surfaces. Packaging used in shipping must withstand vibration, stacking pressure, and frequent handling.

High-quality adhesive packing tape ensures consistent sealing without lifting or peeling, even during long-distance transportation.

Choose the Right Film Thickness

Film thickness affects durability and tear resistance. Thicker films are better suited for industrial and commercial shipping environments where cartons face higher stress.

Choosing appropriate packaging tape thickness helps maintain seal integrity and prevents breakage during transit.

Evaluate Shipping and Storage Conditions

Environmental conditions such as temperature, humidity, and storage duration play a major role in tape performance. Some tapes may lose adhesion in extreme conditions if not designed for such use.

Reliable BOPP tape for packaging is engineered to perform consistently across varying storage and shipping environments.

Check Compatibility With Application Method

Packaging operations may use manual application or automated sealing machines. The tape selected must unwind smoothly and apply evenly to avoid delays or uneven sealing.

Using packing tape for shipping that supports your application process improves efficiency and packaging consistency.

Assess Usage Volume and Cost Efficiency

High-volume packaging operations require tapes that offer long-lasting performance without frequent replacement. Selecting cost-effective tape does not mean compromising on quality.

Durable BOPP packing tape helps reduce rework, minimise wastage, and control overall packaging costs.

Look for Consistent Manufacturing Quality

Consistent quality ensures predictable performance across different batches of tape. Variations in adhesive or film quality can lead to uneven results.

Goodwill Adhesive Tapes focuses on delivering reliable adhesive tape solutions that meet industrial, commercial, and logistics packaging standards.

Using professionally manufactured adhesive packing tape supports dependable packaging outcomes.

Test Before Large-Scale Use

Before finalising a tape for large-scale use, conducting small trials helps verify performance under real packaging conditions. Testing allows businesses to identify the best tape specification for their specific needs.

Conclusion

Choosing the right BOPP packing tape requires careful evaluation of packaging weight, adhesive strength, film thickness, environmental conditions, and application methods. Making informed decisions ensures secure sealing, reduced product damage, and efficient shipping operations.

By selecting high-quality BOPP packing tape suited to your packaging and shipping requirements, businesses can achieve consistent performance and long-term operational reliability.

If you are looking for reliable BOPP packing tape that meets industrial and commercial packaging requirements, Goodwill Adhesive Tapes offers solutions designed for consistent performance and secure sealing.