Dec 08, 2025

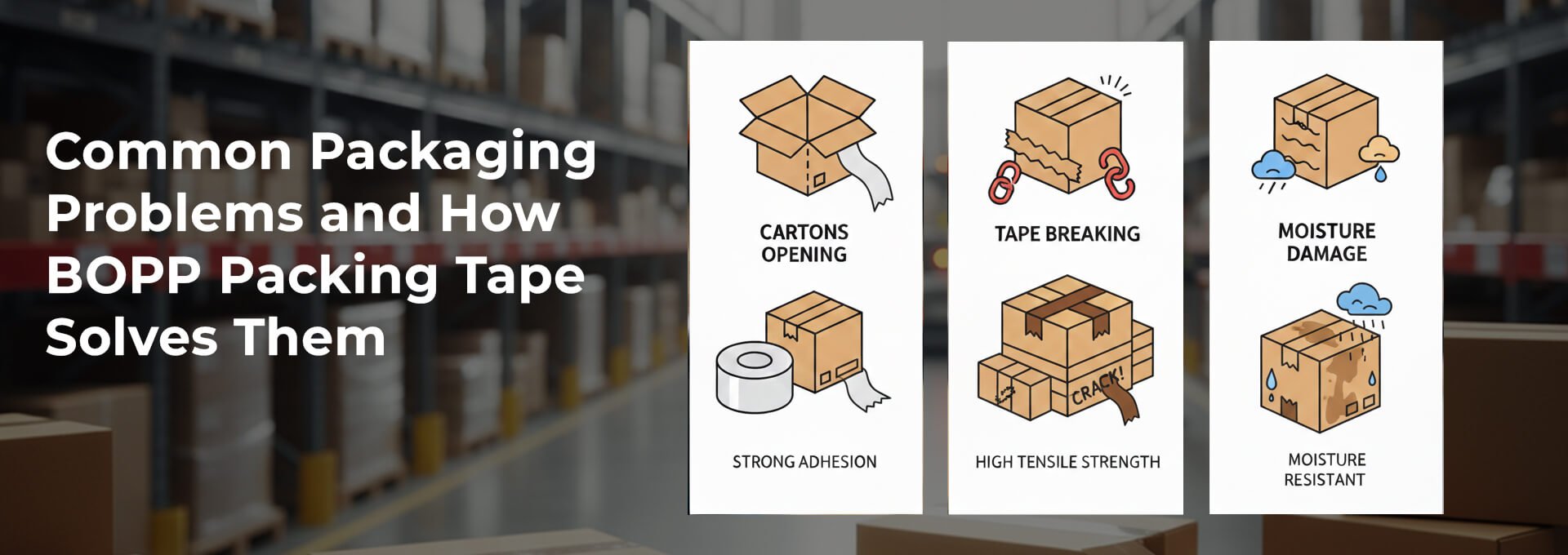

Common Packaging Problems and How BOPP Packing Tape Solves Them

Packaging plays a critical role in protecting goods during storage and transportation. However, many businesses face recurring packaging issues that lead to damaged products, increased costs, and customer dissatisfaction. Most of these problems are linked to improper sealing materials or poor tape performance.

Using the right BOPP packing tape can address many common packaging challenges and help ensure secure, reliable shipment of goods.

Cartons Opening During Transit

One of the most frequent packaging problems is cartons opening while in transit. This usually happens due to weak adhesion or tape failure under load stress.

High-quality adhesive packing tape provides strong bonding to carton surfaces, helping keep packages securely sealed even during long-distance transportation and repeated handling.

Tape Peeling or Lifting From Carton Surfaces

Tape lifting or peeling often occurs when adhesive quality is inconsistent or incompatible with carton material. Dust, surface coating, or rough textures can further weaken adhesion.

Reliable packaging tape is designed to bond effectively with common packaging materials, reducing the chances of peeling and seal failure.

Tape Breaking Under Load Pressure

Heavy cartons place significant stress on tape seals, especially during stacking and movement. Low-strength tapes may tear or stretch excessively, compromising package integrity.

Durable packing tape with sufficient tensile strength helps maintain secure seals and prevents breakage under load pressure.

Damage Caused by Moisture and Environmental Conditions

Exposure to humidity, temperature changes, or storage variations can affect tape performance. Inferior tapes may lose adhesion or weaken over time.

Well-manufactured BOPP tape for packaging offers resistance to moisture and temperature changes, supporting consistent performance across different environments.

Inconsistent Sealing in High-Volume Operations

In fast-paced packaging environments, uneven tape application or poor unwinding can slow operations and cause sealing inconsistencies.

Smooth-unwinding packing tape for shipping supports efficient application, whether used manually or with automated sealing equipment.

Increased Rework and Packaging Costs

Packaging failures often lead to re-sealing, re-packing, and product replacement, increasing operational costs and labour effort.

Using dependable BOPP packing tape reduces rework, minimises wastage, and supports cost-effective packaging operations.

Lack of Professional Packaging Appearance

Poor sealing not only affects product safety but also impacts brand presentation. Loose or uneven tape application creates an unprofessional appearance.

Clear and consistent adhesive packing tape helps maintain clean, organised, and professional packaging standards.

Choosing the Right Packaging Solution

Selecting the right tape plays a key role in solving packaging challenges. Quality, consistency, and proper application all contribute to reliable sealing outcomes.

Goodwill Adhesive Tapes focuses on delivering adhesive tape solutions designed to meet the demands of industrial, commercial, and logistics packaging environments.

Using professionally manufactured BOPP packing tape helps businesses address common packaging problems and maintain secure, efficient operations.

Conclusion

Packaging problems such as carton opening, tape failure, moisture damage, and rework can significantly impact business efficiency and customer satisfaction. Many of these challenges can be resolved by selecting the right sealing material.

By using high-quality BOPP packing tape, businesses can improve packaging reliability, protect goods during transit, and maintain professional standards across their supply chain.

Frequently Asked Questions

Why does packing tape fail during shipping?

Packing tape may fail due to weak adhesive quality, incorrect application, heavy carton weight, or exposure to moisture and temperature changes during transit.

Is BOPP packing tape suitable for heavy cartons?

Yes. When selected with the right film thickness and adhesive strength, BOPP packing tape provides reliable sealing for medium to heavy cartons used in industrial and commercial packaging.

How can I prevent cartons from opening during transport?

Using high-quality BOPP packing tape, applying consistent pressure during sealing, and ensuring clean carton surfaces can significantly reduce the risk of cartons opening during transport.

Does humidity affect the performance of packing tape?

Yes. High humidity and temperature variations can weaken inferior tapes. Quality BOPP packing tape is designed to perform consistently under varying environmental conditions.

How many layers of tape are recommended for secure packaging?

The number of tape layers depends on carton weight and shipping conditions. Heavier or high-value shipments often require reinforced sealing with multiple tape strips.

Can BOPP packing tape be used with automated sealing machines?

Yes. BOPP packing tape is compatible with both manual application and automated sealing machines when manufactured to consistent quality standards.

How does good packing tape reduce packaging costs?

Reliable tape reduces carton failures, rework, and product damage, helping businesses lower overall packaging and logistics costs.